Industrial Fruit Mango Orange Dragon Fruit Washing Waxing Grading Line

Industrial fruit mango orange dragon fruit washing waxing grading line Introduction: Industrial fruit mango orange drago

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | KS G3 |

| Weight | 1t |

| Capaicty | 1-5t |

| Feature | Labor Saving |

| Application | Fruit Vegetable Food |

| Transport Package | Wooden Case |

| Specification | stainless steel |

| Trademark | KS |

| Origin | Shandong, China |

| HS Code | 8438800000 |

| Production Capacity | 30 Sets/Month |

Product Description

Industrial fruit mango orange dragon fruit washing waxing grading line

Introduction:

Industrial fruit mango orange dragon fruit washing waxing grading line is specially designed to sort and grade kinds of fruits and vegetables according to the weight. It is widely used for grading apples, pears, peaches, plums, apricots, kiwi fruits, mangoes, oranges, navel oranges, melons, dragon fruits, pineapples, tomatoes, sweet potatoes, onions and potatoes etc.

Application

It is widely used for grading apples, pears, peaches, plums, apricots, kiwi fruits, mangoes, oranges, navel oranges, melons, dragon fruits, pineapples, tomatoes, sweet potatoes, onions and potatoes etc.

Main features

1. High processing capacity, grade adjustable, can be divided into 3~6 grades and above.2. High classification accuracy, high grading speed, simple operation, general staff can operate it.3. Product no damage, after special design this machine can also grade the eggs.

Technical parameters

Model | KS-G6 |

Capacity | 1~5t/h |

Grade qty | 3~6 grades |

Power | 2.2kw |

Voltage | 220/380v |

Weight | 2000kg |

Dimensions | 9500*1300*900mm |

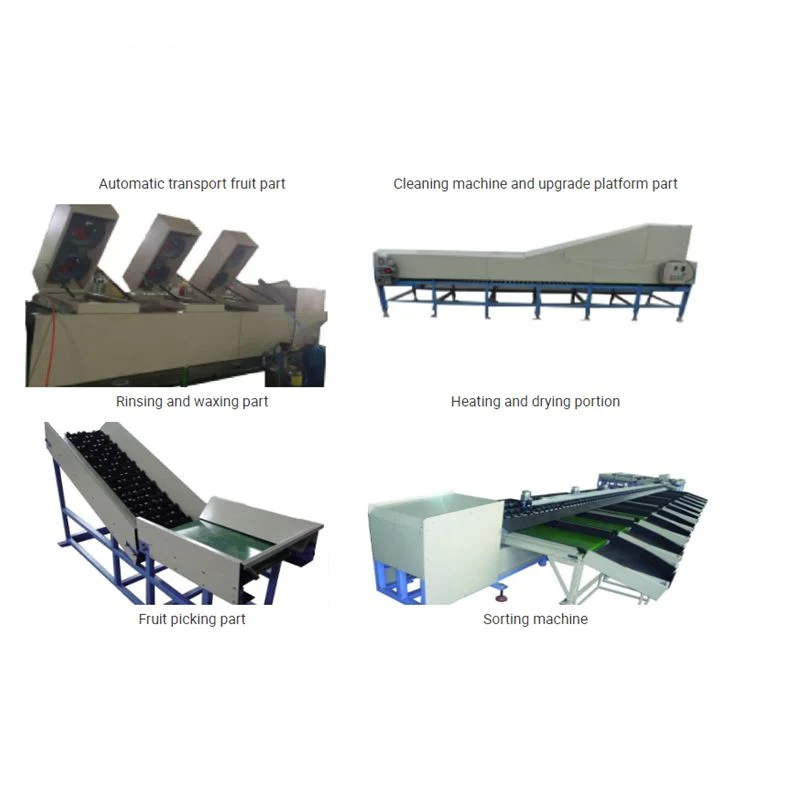

Detailed pictures of fruit grading machine

Fruit processing grading line

This fruit processing grading line consists of fruit conveying and brush washing polishing, waxing, air drying and roller type sorting functions. Our machine can used for all kinds of round or nearly round fruits and vegetables, such as: orange, navel orange, lemon, Hu You, tomato, peach,apple and other vegetables' processing.

1.washing and waxing part

a. for cleaning and waxing fruits, such as apple, citrus, navel orange, honey pomelo et

b. to make the fruit appearance look bright, and improve the fruit price for sale. At the same time,

after waxing, a layer of wax membrane will be coated on the fruit to keep the fruit away from

bacteria and elongate the fruit storage time.

2. Electric Grading part

a.This electronic fruit grader is efficient and precise. It's widely used for grading apples, pears, persimmons,onions,lemons,mangos,pomelo,jujube,and other round fruits.

b.It is controlled by PLC, and is highly intelligent. Weighing, logic calculation, counting are

integrated.

c.Tetrafluoroethylene is covered onto the working surface to keep the machine running stably with low noise and increase the shelf life of the machine. The operation and maintenance of the machine is easy and laborsaving.

Our company

About Jinan Keysong Machinery

Jinan Keysong Machinery was founded in 2013, it is located at Jiyang Economic Development Zone. Since its inception, it is specializing in the manufacture, research, development, sales and after-sales of food extrusion machine, puffed food production line, fruit and vegetable washing and drying processing line.

Puffed food equipment: food extruder, twin screw extruder, single screw extruder, breakfast cereals/corn flakes production line, fried and baked snacks production line, pet food production line, fish feed production line, textures soya protein production line, modified starch production line, bread crumb production line, laboratory twin screw extruder, nutritional rice production line, etc.

Vegetable washing and drying machinery: brush washing peeler, fully automatic roller cleaning and peeling machine, vegetable and fruit slicer, blanching and pasteurization equipment, vegetable and fruit drying machine, tunnel type dryer.

Our customersOur certificates

Our service

1. OEM & ODM

2. One year guarantee and life-time maintenance service.

3. Consultation service before, during, and after sales.

4. Provide factory layout according to your factory size in advance;5. Provide the basic formula;

6. Debugging of machines until all are functional.

7. Training the customers how to operate and maintain the machines correctly.

8. Offer new product techniques and recipes timely.

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers'

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.